The Importance of Particle Counting in a Laboratory

Particle counting is an essential component of air quality monitoring in laboratories across scientific and technological disciplines such as biotechnology, biopharmaceutical production, nanotechnology, and semiconductor development and manufacturing. Any laboratory involved in processes or products sensitive to environmental contamination must prioritize precise particle counting to ensure optimal conditions.

Particle Counting in a Laboratory

Maintaining stringent sterility and air purity is crucial in the manufacturing of pharmaceuticals, superconductors, and other high-quality products. Ensuring that finished products are contaminant-free and comply with regulatory standards is vital. Common contaminants such as volatile organic compounds (VOCs), perfumes, and dust can compromise the integrity, safety, and purity of the final product. The use of particle counting instruments, which also serve for particle sizing is indispensable for monitoring air quality parameters in modern laboratory settings. In addition, particle counting aids in identifying faulty equipment, such as loose seals or issues within the HVAC system, that may introduce contaminants into the laboratory environment.

Types of Particle Counters

A variety of particle counters are available for laboratory use. In many of these instruments, particles are counted as they pass through a detection chamber, where they are illuminated by a high-energy light source. The total number of particles present in an air sample is then detected using an array of methods.

Light Scattering Particle Counting

In light-scattering particle counting, particles in the detection chamber sample deflect light, which is then measured using a photosensor. This method is analogous to determining an object's mass by submerging it in a filled bath and measuring the displaced water.

Light Obscuration

In light obscuration, or light-blocking devices, the photo-sensor detects any reductions in light arising from the presence of particulate matter in the sample being analyzed.

Imaging Particle Counting

Also known as direct imaging particle counting, this method involves the use of sophisticated computer imaging software. High-definition video captures and analyzes the number of particles in a sample illuminated by a high-intensity light beam.

Particle counting instruments come in various sizes and serve different functions in a laboratory setting. Small, portable, handheld particle counters are ideal for taking measurements at multiple locations, ensuring regular checks on air quality throughout the lab. Larger particle counters are often stationary and used to analyze greater volumes of air, operating on a 24/7 basis for long-term air quality monitoring. This continuous monitoring is crucial for early identification of contamination sources.pr

Highly specialized laboratories handling ultra-sensitive materials may require a condensation particle counter. Conventional optical particle counters generally cannot detect particles smaller than 50 nm. In contrast, condensation particle counters can detect particles as small as 2 nm. They achieve this through heterogeneous nucleation, a process where particle nuclei are supersaturated until they condense, followed by light scattering. This process is analogous to how nucleation centers in the atmosphere form clouds through condensation but on a much smaller scale.

Particulate matter detectable in the air can be classified into two types: viable and non-viable particles. Viable particles are living microorganisms present in the air, including bacteria, fungi, and fungal spores, with a size distribution ranging from 0.2 to 30 μm. To count viable particles, they must first be collected without harming the microorganisms. Subsequently, the particles are inoculated on an appropriate culture medium to grow and be counted.

Non-viable particles are non-living but may transport living particles. The general size range of monitored non-viable particles is between 0.5 to 5 μm.

Meeting and Maintaining Air Quality Standards

Many types of modern laboratory operations must often take measures to ensure that air quality is maintained to the highest of standards. These standards become even more stringent when cleanrooms are required, such as in the manufacture of semiconductors, disk drives, or aerospace components, or in the development and production of pharmaceuticals and biotech products, such as vaccines or monoclonal antibodies.

In high-tech industries like these, components, ingredients, instruments, or products may be highly sensitive to even the slightest hint of contamination. Cleanroom air quality standards are thus highly demanding, and require innovative solutions to monitor and detect particulates in the air, and to report any deviations from standards if they occur in a timely fashion.

Air quality parameters in biotech, biopharmaceutical, and many other modern laboratory environments must therefore be continuously monitored and assessed. One way to help you observe and control the optimum conditions in your lab, and to maintain a consistent environment that meets all regulatory and product specification guidelines, is to use an automated, computerized laboratory monitoring and control system, such as XiltriX.

XiltriX includes particle counting as part of its monitoring processes. The system can be set up to monitor remote particle counters and will send alarm notifications to relevant users if the particle number, size, or air quality parameters deviate from the specified standards.

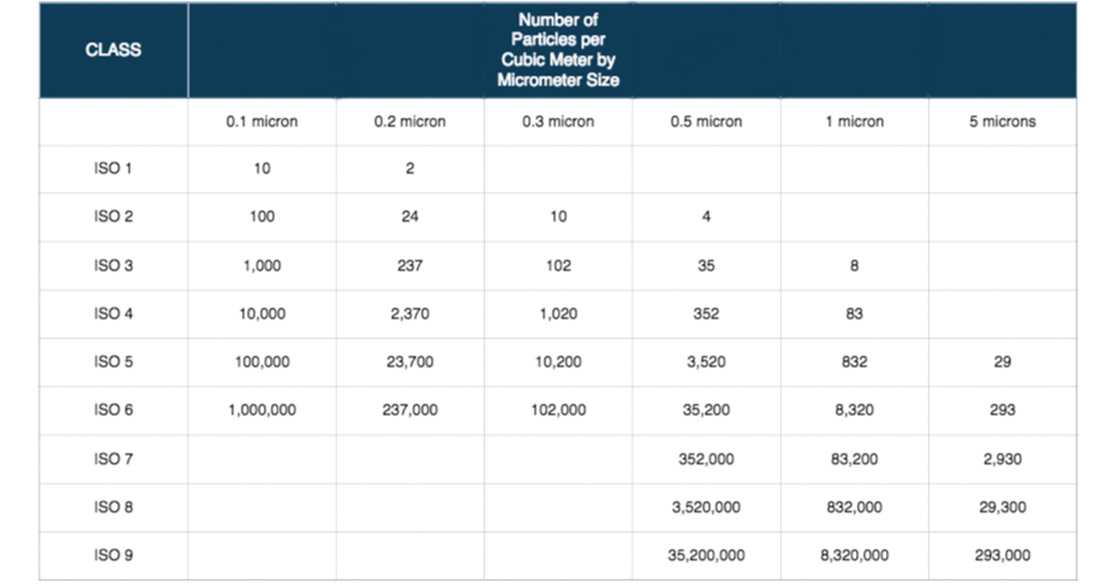

The system also records all the air quality and particle counting results, which can subsequently be used to provide evidence during quality control audits, validation exercises, and reporting requirements. Cleanrooms in particular have strictly defined limits as to what level of particulate matter is acceptable in them to meet mandated quality standards. These standards contain 9 classes, each of which must adhere to different testing and parameters.

Read more about monitoring air quality and other environmental conditions in our eBook: Laboratory Environmental Monitoring.

See the charts below for a break-down of each classification:

Airborne Particulate Cleanliness Class Comparison:

Airborne Particulate Cleanliness Classes (by cubic meter):

A monitoring system such as XiltriX, which provides warning alarms in real-time should there be any problem with particulate levels, is therefore an indispensable feature of the modern laboratory.

To learn more about how different factors affect laboratory air quality, read our white paper: Air Quality in the Lab.